Description

Description

Vertical Ring Die Pellet Machine For Processing sawdust pellets – Independently Developed by Our Company

Our vertical ring die pellet machine is independently developed and manufactured by our company, integrating the advantages of both domestic and international pelletizing technologies.

The machine features a vertically positioned flat die with a dual-layer compression zone, significantly improving production efficiency and structural stability. Both the die and rollers are made of high-alloy wear-resistant materials, ensuring long service life and consistent performance.

With its reasonable design, unique structure, high efficiency, and durable components, this pelletizer is ideal for large-scale pellet production in biomass, feed, fertilizer, and other processing industries.

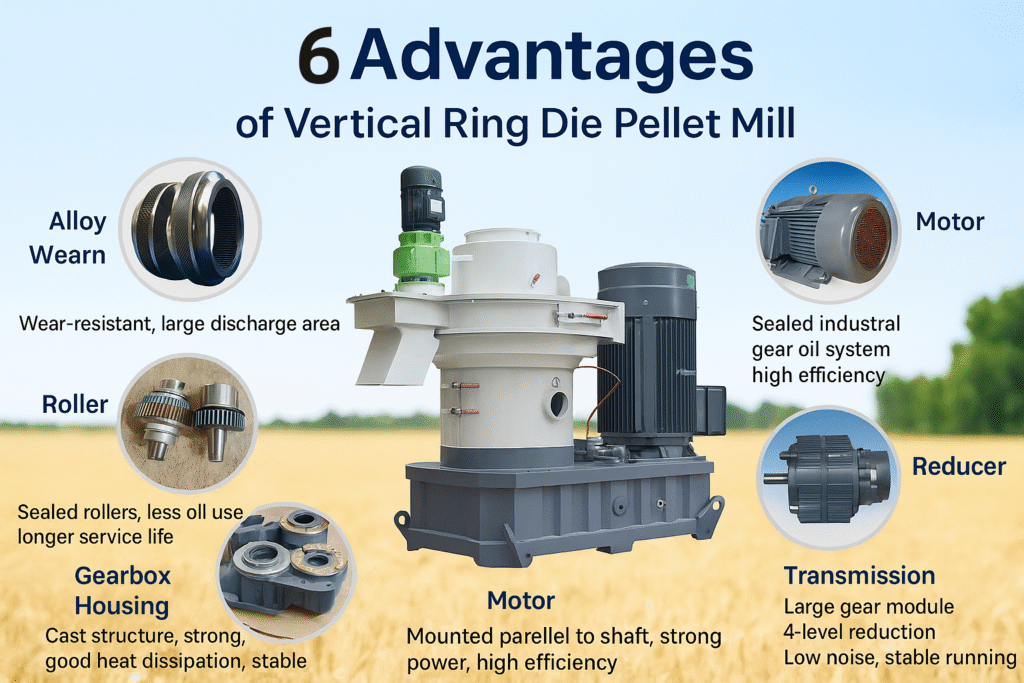

Advantages

Performance Features of Vertical Ring Die Pellet Machine

1.Flat Die with Vertical Installation

Direct feeding design with a wide range of raw material adaptability. The vertical structure ensures excellent heat dissipation.

2. Double-Layer Vertical Die

Increases die utilization and reduces production costs, offering a higher cost-performance ratio.

3. Integrated Main Shaft Design

Ensures precise concentricity of the equipment, significantly reducing mechanical failure rates.

4.Fully Automatic Intermittent Lubrication System

Extends the service life of vulnerable components and reduces maintenance requirements.

5.Combination of Centrifugal Force and Extrusion Pressure

Enhances pellet density, smoothness, and forming rate while effectively increasing overall output.

Models & Specifications

| Model | Power (kW) | Weight (t) | Capacity (t/h) | Pellet Size (mm) | Overall Dimensions (mm) L×W×H |

| LM450 | 55 / 75 | 3 | 0.8 – 1.2 | Φ6 – Φ12 | 2200 × 1400 × 2200 |

| LM560 | 90 / 110 / 132 | 4.5 | 1 – 2 | Φ6 – Φ12 | 2300 × 1500 × 2200 |

| LM600 | 132 / 160 | 4.8 | 2 – 2.5 | Φ6 – Φ12 | 2300 × 1500 × 2200 |

| LM700 | 160 / 185 | 5 | 2.5 – 3 | Φ6 – Φ12 | 2300 × 1500 × 2200 |

Reviews

There are no reviews yet.