Description

Description

Hookah Charcoal Rotary Press is mainly used for pressing charcoal powders into tablet shapes of briquettes with high density. The mold of rotary press can be customized flexibly.

This mechanical charcoal press is of the double-press type, with two sets of filling devices and two sets of pressing wheels. The machine has a double frequency speed control function, the filling depth and the thickness of the pressed sheet can be adjusted freely. The machine is equipped with a cushioning device, which automatically stops the machine when it is overloaded, and with a broken punch protection device, which prevents damage to the parts.

The rotary press complies with GMP requirements. When people run the shisha charcoal production line, the auxiliary equipment also can be equipped, like a hoover, a crusher, a mixer, drying oven, etc.

Features

(1) It is installed with forcing feeding system to ensure enough material to be fed when running.

(2) It can be tested and adjusted without stopping.

(3) All controls and operating parts are well equipped centrally and easy to operate.

(4) The machine is a mature machine tested by numerous users with low maintenance cost and failure rate, which can ensure 24 hours continuous production.

(5) Due to its high pressure, smooth rotation, stable performance, safe and accurate features, it has more wider applications in industry fields, so various kinds of power materials can be pressed, like sugar material, medical powder, etc.

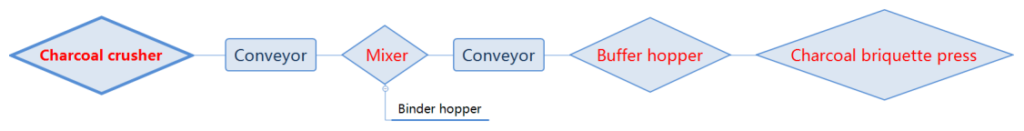

Production Flowchat of Shisha Charcoal Briquette

Specifications

Model: LMXZ-19

Motor power: 5.5kw,6 pole

Electricity: 380V50HZ,3-Phase

Feeder motor power: 0.37kw

Capacity: 45,600 pcs/hour

Max. Rotating speed: 20RPM

Max.pressure: 120KN

Depth of mold: 30mm

Outlet port: 2 pcs

Mold Outer Size: Round tablet Φ35mm, central hole Φ10mm

Thickness data: 12 mm

Thickness adjusting range: 6mm

Holes in Mould: 19 holes(Diameter<40mm)

Machine size:0.92×0.89×1.54m

Weight: 1400kg

Working Video

Reviews

There are no reviews yet.