Description

The Hammer Crusher (also called Hammer Mill) crushes materials through impact, available in single-rotor and double-rotor designs. It can reduce material sizes from 600-1800mm down to ≤25mm in a single stage. Ideal for cement, chemical, power, and metallurgy industries, it efficiently processes medium-hard materials like limestone, slag, coke, and coal.

Crushing Principle

The hammer crusher primarily relies on impact energy to crush materials. During operation, the motor drives the rotor to rotate at high speed. The material is evenly fed into the crushing chamber, where the high-speed rotating hammers strike, shear, and tear the material, causing it to be broken. At the same time, the material’s own gravity causes it to be propelled from the high-speed rotating hammers toward the frame’s baffle and screen bars. Materials larger than the screen hole size are retained on the screen and continue to be struck and ground by the hammers until they are crushed to the required discharge size, and finally, the material is expelled through the screen.

The hammer crusher is divided into several types: single-stage hammer crusher, hammer crusher, sand maker, vertical shaft hammer crusher, reversible hammer crusher, and ring hammer crusher. The ring-type coal crusher, which replaces the hammers with steel rings, is a variant of the hammer crusher. It uses a combination of high-speed impact and low-speed compression to break materials, allowing for the production of finer products. It is mainly used for crushing coal for power plants but can also be used for crushing gypsum, salt chemical raw materials, and some medium-hard materials.

Types of Hammer Crushers:

- By the number of rotors: They are classified into single-rotor and double-rotor types.

- By the rotor rotation direction: They are classified into irreversible and reversible types.

- By the arrangement of hammers: They are classified into single-row and multi-row types. In the single-row type, the hammers are installed on the same rotational plane, while in the multi-row type, the hammers are distributed across several rotational planes.

Applications of Hammer Crusher

It is mainly used for crushing coal, salt, gypsum, bricks, limestone, and other medium-hard and brittle materials. It is also used to crush materials with fibrous structure, strong elasticity, and toughness, such as scrap wood, paper, or asbestos cement waste to recover asbestos fibers, etc. In addition, the hammer crusher is not only used in crushing production lines and sand-making production lines, but can also replace cone crushers in mineral processing lines. It is commonly used in refractory plants, cement factories, glass factories, and other industries.

Structure & Components

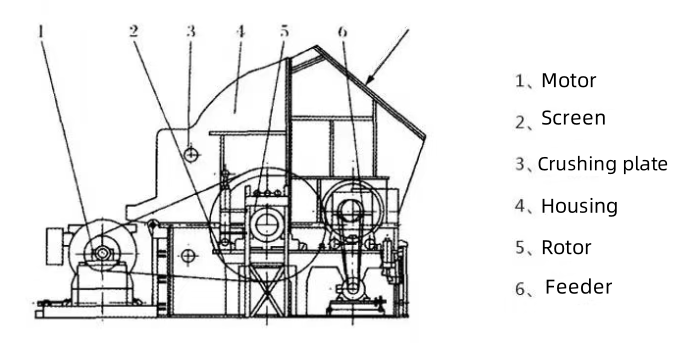

A hammer crusher consists of a housing, rotor, hammers, impact liners, and screen plates.

The main shaft of the crusher is equipped with several rows of hanging hammers. The pin holes along its circumference are fitted with pin shafts, which hinge the hammers between each row of hanging hammers. When the hammers are worn, the working surface can be replaced.

Hammer crusher structure diagram

- Machine Housing The housing of the hammer crusher consists of the lower body, upper rear cover, left side wall, and right side wall, all connected together by bolts. The upper part is fitted with a feed inlet, and the interior walls of the housing are lined with high-manganese steel plates, making it easier to replace the liners after wear. The lower body is welded from carbon structural steel plates, and high-manganese steel is used to weld the bearing supports on both sides to support the rotor bearings.

- Rotor The rotor is the main working component of the hammer crusher. It consists of the main shaft, hammer disc, pin shaft, hammers, and other parts. The disc is evenly perforated with distributed pin holes, and the hammers are suspended by pin shafts. To prevent axial movement of the disc and hammers, locking nuts are used to secure the pin shafts at both ends.

3. Main Shaft The main shaft is the key component that supports the rotor in the hammer crusher. It bears the weight and impact forces of the rotor and hammers, so the material of the main shaft needs to have high toughness and strength. The main shaft is made of alloy steel and is processed through ultrasonic inspection and heat treatment to achieve proper conditioning.

4. Hammers The hammers are crucial working components of the hammer crusher. The quality, shape, and material of the hammers directly determine the crusher’s production capacity. The kinetic energy of the hammers is proportional to their weight; the heavier the hammers, the greater the kinetic energy, resulting in higher crushing efficiency. A wide range of hammer weights are available, with smaller hammers weighing 15 kg and larger hammers reaching up to 298 kg. Various hammer weights can be customized according to customer requirements. The hammers are made using a new multi-element high-chromium manganese steel composite casting, providing a service life several times longer than that of standard hammers.

5. Liners and Impact Plates The hammer crusher strikes the ore at high speed with the hammers, subjecting the ore to extreme velocity and kinetic energy. To prevent wear on the frame, the interior walls of the frame are lined with manganese steel. The impact plates are cast from high-manganese steel, quenched, and undergo strengthening treatment, ensuring superior wear resistance and impact resistance for both the liners and impact plates.

Features

- The working hammers are cast using a new process, offering excellent wear resistance and impact resistance.

- The required particle size can be adjusted according to customer specifications.

- The hammer crusher body structure is sealed, addressing dust pollution in the crushing workshop and preventing dust leakage from the machine.

- The overall design is aesthetically pleasing, compact, with fewer wearable parts and easy maintenance, making it an upgraded product.

- The structure is compact, appearance is attractive, wear resistance is excellent, and maintenance is convenient.

Working video of hammer crusher

Looking for a reliable and efficient solution to crush a variety of materials? Our hammer crushers are designed for superior performance, durability, and versatility. Whether you need to crush coal, limestone, or other medium-hard materials, our hammer crushers provide the power and precision you need. Contact us today to learn more and find the perfect crusher for your business needs!

Leave a Reply